Solar Concentrated Power Technologies: A Comprehensive Overview and Their Application in Australia

Solar Concentrated Power (CSP) is a sustainable and efficient method of harnessing solar energy to generate electricity and heat. Unlike conventional solar photovoltaic (PV) systems, which convert sunlight directly into electricity, CSP technologies focus sunlight using mirrors or lenses to generate intense heat. This heat produces electricity or provides high-temperature thermal energy for various applications.

In this blog, we will explore different CSP technologies, such as Parabolic Troughs, Linear Fresnel Reflectors, Solar Power Towers, and Solar Dish/Engines. We will also examine their potential applications, advantages, and disadvantages within the Australian context and how they can contribute to industrial decarbonisation.

1. Parabolic Troughs

Image source: Science direct

Parabolic troughs are one of the most established CSP technologies. They consist of long, parabolic-shaped mirrors that concentrate sunlight onto a receiver tube located along the focal line of the parabola. Heat-absorbing fluid flows through the receiver, generating high-temperature steam that drives a turbine to produce electricity.

Pros:

Mature technology with a proven track record.

Good efficiency and energy storage capabilities.

Applicable to a wide range of industrial processes.

Cost-effective for electricity generation.

Cons:

High water usage for cooling, which can be a concern in water-scarce regions.

Limited heat storage capacity for extended periods of operation.

In Australia, the Solar Energy Generation Project in the Northern Territory uses parabolic trough technology to provide industrial process heat to a manganese mine. This example highlights the potential of CSP for decarbonising industrial processes.

Parabolic Trough images source Energy.gov

2. Linear Fresnel Reflectors

Linear Fresnel Reflectors utilize flat mirrors to concentrate sunlight onto a linear receiver, similar to parabolic troughs. The key difference is in the mirror design, which is flat instead of parabolic.

Linear Fresnels system. Image source: The U.S Department of Energy.

Pros:

Simpler design and lower cost compared to parabolic troughs.

Suitable for both electricity generation and industrial heating.

Reduced land and materials requirements.

Cons:

Generally lower efficiency than parabolic troughs.

Limited energy storage capabilities for extended operation.

In Australia, the Liddell Power Station in New South Wales utilises Linear Fresnel Reflectors to provide steam for power generation. This technology is an excellent choice for retrofits and process heat applications.

At Enaxiom we believe that the Linear Fresnels system can be used to replace gas-fired heating systems within manufacturing processes, and this is why we have partnered with world renowned manufacturer Ecotherm to increase the use of this technology in Australia and further decarbonise heat processes.

Compact Linear Fresnel field at Liddell Power Station, Australia.

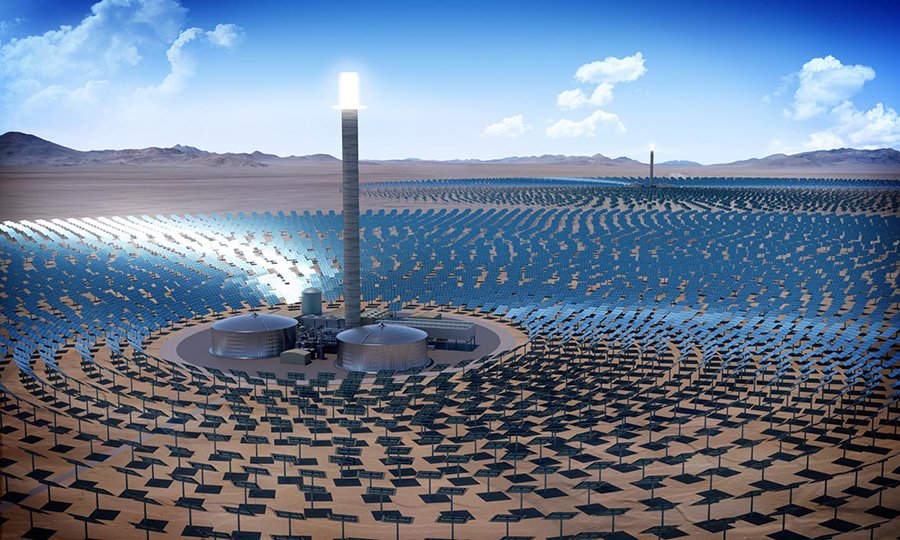

3. Solar Power Towers

Image source: The U.S Department of Energy.

Solar Power Towers use an array of flat mirrors or heliostats to focus sunlight onto a central tower receiver. The high-temperature heat generated in the receiver is used to produce steam, which drives a turbine for electricity generation.

Pros:

High efficiency and energy storage capacity.

Capable of producing high-temperature heat for various industrial processes.

Well-suited for large-scale electricity generation.

Cons:

High upfront construction costs.

Bird and insect hazards around the tower.

Water usage for cooling can be significant.

SolarReserve's Copiapó Solar Plant in Chile showcases the potential of Solar Power Towers for industrial applications. In Australia, RayGen in partnership with Photon Energy Group is looking to install a 200-megawatt plant touted to cost around $600 million AUD. This technology can be ideal for large-scale power generation and industrial heat applications in areas with abundant sunlight.

Image source: Heliscope solar power energy news.

4. Solar Dish/Engines

Image source: The U.S Department of Energy.

Solar dish/engine systems consist of a parabolic dish that focuses sunlight onto a receiver at the dish's focal point. Stirling engines or Brayton cycle engines convert the heat to electricity.

Pros:

High efficiency and energy storage capabilities.

Suitable for remote power generation.

Scalable and versatile.

Cons:

Limited industrial process heat applications.

Smaller scale compared to other CSP technologies.

While Solar Dish/Engines are less common in Australia, they can find use in remote areas where grid connection is challenging. The CSIRO Energy Centre in Newcastle has used a small-scale version for research and testing.

Image source: International Rivers.

Technical and Economic Application in Australia

Australia possesses vast amounts of sunlight and offers an ideal environment for CSP technologies. Parabolic troughs and Linear Fresnel Reflectors can be effective in providing industrial process heat for mining, manufacturing, and food processing. Solar Power Towers and Solar Dish/Engines are well-suited for large-scale electricity generation, especially in remote areas.

The economic feasibility of CSP technologies in Australia depends on factors such as location, available sunlight, project scale, and government incentives. While the upfront costs can be substantial, CSP systems offer long-term advantages, including low operating costs and reduced carbon emissions.

Decarbonization and Industry Applications

CSP technologies play a crucial role in industrial decarbonisation. According to ARENA 48% of industrial energy production was for heat less than 250°C which aligns with the Fresnels system. Industries that require high-temperature heat, such as cement, steel, and chemical manufacturing, can benefit from CSP's ability to provide emissions-free, high-temperature thermal energy. Additionally, CSP systems can integrate energy storage, making them valuable for stabilising the grid.

In conclusion, CSP technologies offer a promising avenue for Australia's transition to a sustainable and decarbonised energy system. While solar panels have their applications, CSP technologies provide a unique solution for addressing industrial process heat and large-scale electricity generation while reducing greenhouse gas emissions. As Australia continues to explore and invest in renewable energy, CSP can significantly contribute to a greener and more sustainable future.